From it's OWL project to maintenance progress

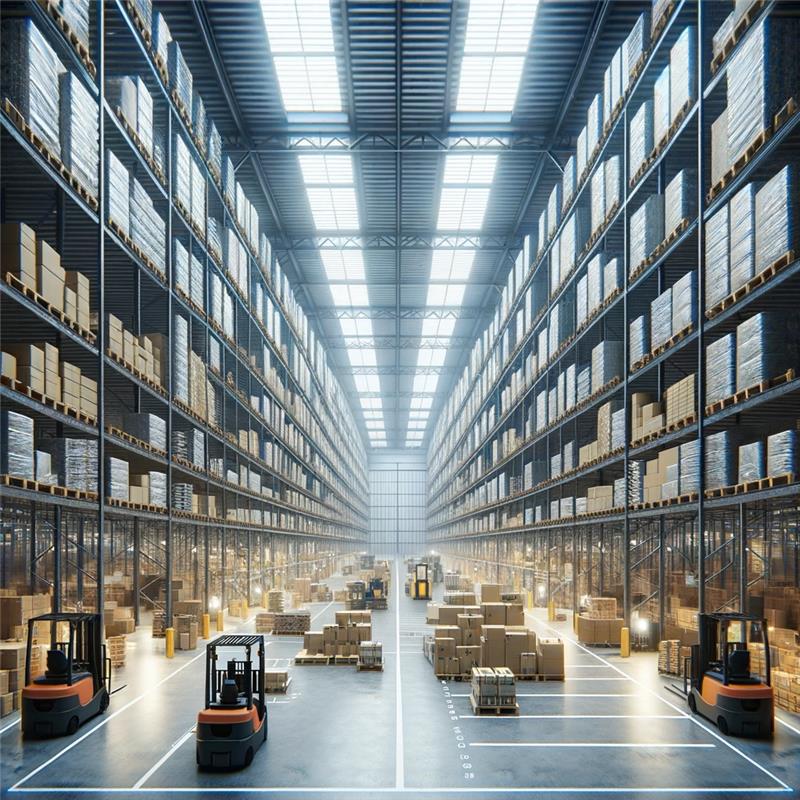

Innovative technologies are revolutionizing the maintenance of automated storage systems: The it's OWL project, a collaboration between Lenze and Fraunhofer IEM, presents a groundbreaking AI-based maintenance assistant. This assistant enables Lenze to plan the maintenance and repairs of its high-bay warehouses efficiently and specifically in order to avoid unplanned downtimes and save costs.

The AI maintenance assistant uses machine learning algorithms to detect and localize critical conditions and potential defects at an early stage. This allows Lenze employees to take targeted maintenance measures before failures occur. The system is particularly cost-efficient because it is based on existing sensors and can therefore be retrofitted without much effort.

The development of the AI maintenance assistant benefited from the high data quality of the Lenze machines and the use of embedded and edge devices, which enable resource-saving processing of large amounts of data. The flexibility of the solution allows Lenze to use it in various areas of automation technology and also make it accessible for smaller budgets.

The EASY project, a cooperation between the Lenze subsidiary encoway and Fraunhofer IEM, was funded by the BMBF. It offers an insight into the future of predictive maintenance and the benefits it will bring to companies.

Source: it's OWL; Fraunhofer IEM; Lenze