Unique benchmark technology in battery recycling

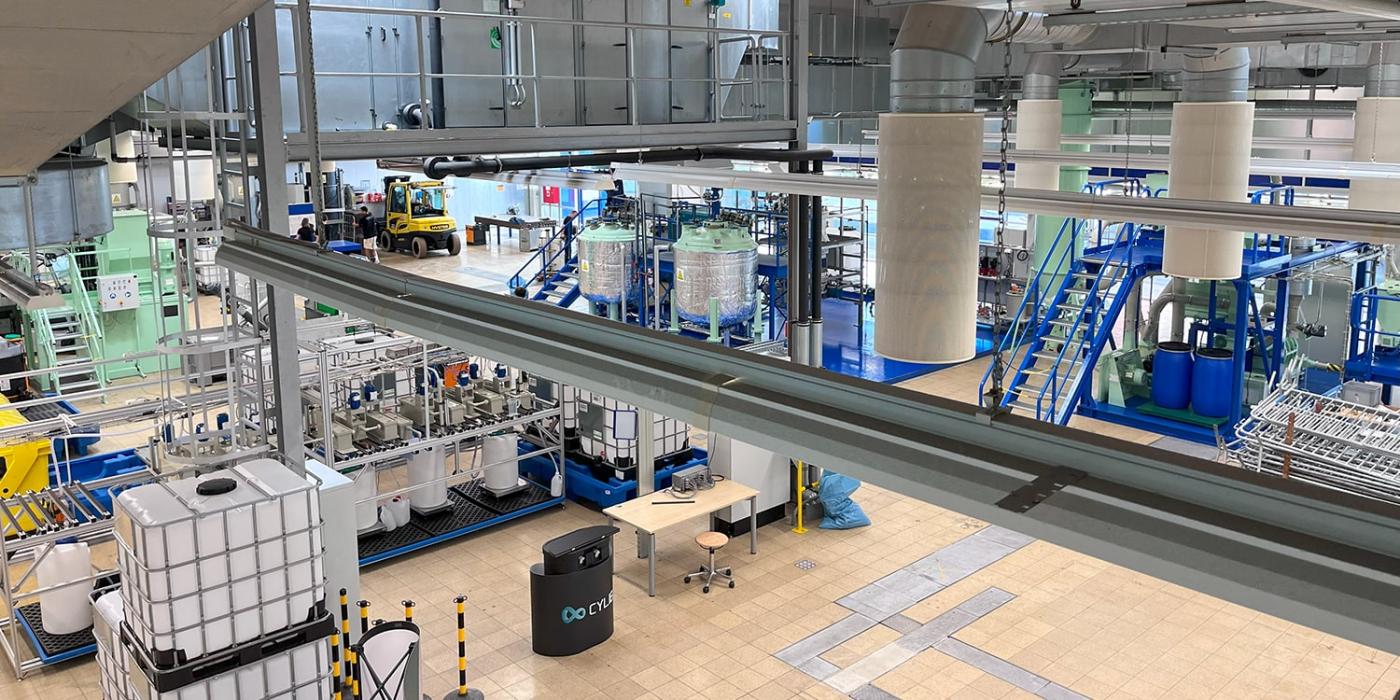

The newly launched pilot line for sustainable battery recycling of lithium-ion batteries enables the recovery of all elements for the first time, including valuable raw materials such as lithium and graphite. The recycling capacity is now 500 kg per day and work is already underway to develop an industrial line that will be able to recycle several thousand tons per year.

The increasing use of batteries in electric vehicles, power tools and renewable energy systems has led to a dramatic increase in battery usage. In Germany alone, the recycling requirement is already around 100,000 tons per year and, according to a study by Fraunhofer ISI, is expected to increase to around 2.1 million tons by 2040. At the same time, Europe is heavily dependent on raw material imports, as all elements relevant to battery production, such as lithium, graphite, cobalt and nickel, have to be imported.

Given the growing need for battery raw materials and a forecast recycling need of around 2.1 million tons by 2040, Cylib's unique recycling process helps to strengthen Europe's independence from raw material imports.

Source: KNUW

Learn more?

NMWP.NRW provides information about the success story from NRW, which was also awarded the Innovation Prize of the State of North Rhine-Westphalia: